Pumpkin

Increase operational reliability and product quality with pumps from Alfa Laval.

Get more out of your production with mixing equipment from Alfa Laval

When liquids need to be moved from A to B in a production, it matters how it happens. Too little pressure, too much turbulence, or an unstable flow can quickly cost both time, money, and product quality.

Alfa Laval’s pumps are developed with precisely these challenges in mind. Some models easily handle gentle transport of sensitive products, while others manage both CIP and high pressures without blinking. And no matter which one you choose, you get a solution that delivers stable performance and requires minimal maintenance.

In short: You get a pump that fits the reality of your production – not just the brochure

Find the right pump for your process

The right pump can be the difference between stable, efficient operation and costly downtime. It should not just move liquid – it should do so gently, reliably, and with as little energy consumption and maintenance as possible.

Fortunately, Alfa Laval has a wide range that covers it all. From classic centrifugal pumps to flexible twin screw solutions. Common to all of them is a focus on operational reliability, energy efficiency, and good handling of even the most demanding products.

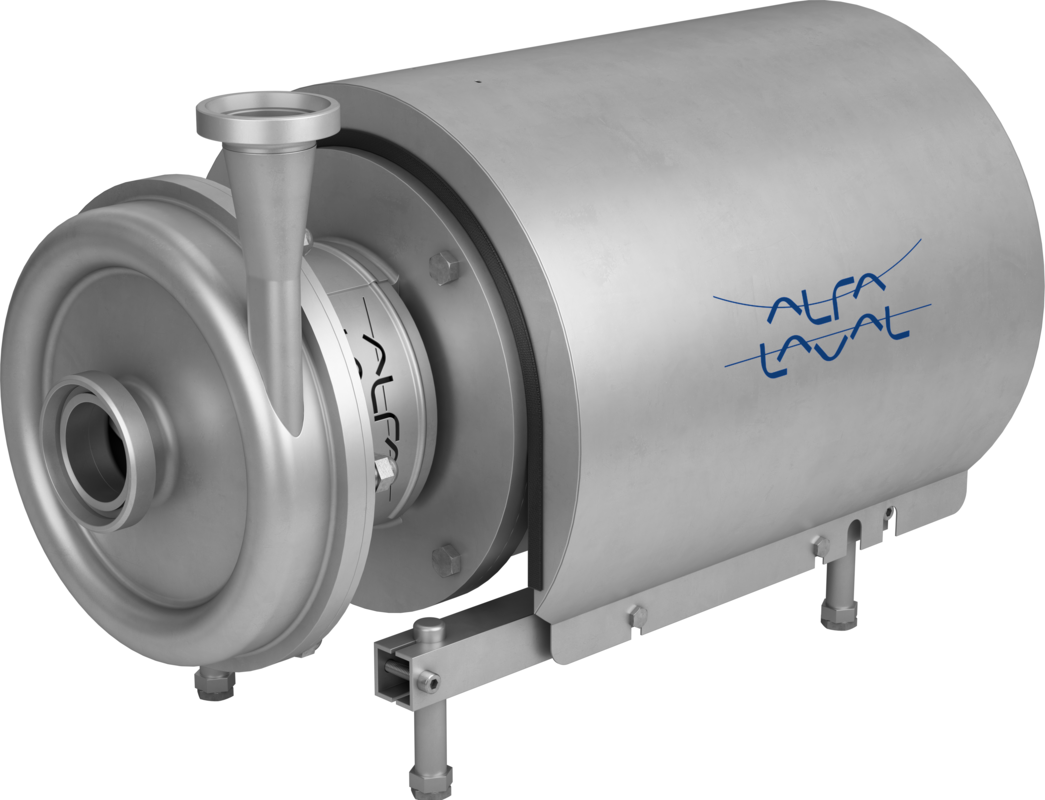

Centrifugal Pumps

Alfa Laval’s centrifugal pumps are a solid choice when you need a pump that just runs – day after day. With their gentle product handling and high capacity, they are ideal for everything from CIP return systems to sensitive productions where product quality must be maintained throughout.

- High energy efficiency: Advanced impeller design reduces energy consumption without compromising performance.

- Gentle product handling: Minimal turbulence protects your product and ensures consistent quality.

- Flexible solutions: Find a solution for everything from high-pressure applications to self-priming and sterile pumps.

- Easy maintenance: Hygienic design makes cleaning quick and efficient with CIP

Piston Pumps

Alfa Laval’s piston pumps are an obvious choice when you need to move low-viscosity products with high pressure without compromising reliability. They are widely used in the food, dairy, and beverage industries as well as for personal care and biotechnological applications.

- High precision: Smooth and stable product flow, even at low viscosities.

- Long lifespan: Robust construction reduces wear and ensures operational reliability.

- Easy service: The design makes it simple to replace wear parts and reduces service time.

- High hygiene: CIP and SIP compatible design.

Lobe Pumps

Alfa Laval’s lobe pumps are ideal when you work with gentle handling of both thin and thick liquids. They ensure stable and consistent flow control, making them particularly suitable for food, pharmaceutical, and biotechnological applications.

- Minimal product impact: Low shear effect ensures the structure and quality of the product.

- Flexibility: Can handle products with both low and high viscosity without affecting the flow.

- High hygiene: Designed for easy cleaning and fully CIP and SIP compatible.

- Low energy consumption: Optimized construction reduces energy consumption and operating costs.

Twin Screw Pumps

Alfa Laval’s Twin Screw pump is a versatile solution for those who want to simplify their setup without compromise. It handles both sensitive products and demanding CIP cleaning without needing to change pumps in between.

This makes it ideal for processes with varying viscosities. With low pulsation and gentle handling, it ensures that your product remains intact while providing high operational reliability and easy maintenance.

- High flexibility: One pump for both product and CIP flow.

- Gentle handling: Low pulsation and minimal shear effect protect the product.

- Increased operational reliability: Robust construction ensures high uptime.

- Easy service: Quick disassembly and simple maintenance.

M Gear Pumps

The M Gear series from Alfa Laval is developed for efficient transfer of small amounts of liquid in both hygienic and industrial processes. They are often used in filling, dosing, and sampling machines.

- Precise dosing: High accuracy ensures consistent product quality.

- Flexible integration: Compact design makes them easy to integrate into OEM machines.

- Quick maintenance: Simple disassembly and replacement of wear parts.

- Sustainable operation: Reduced material waste and energy consumption.

Read more about Alfa Laval’s wide range of mixing equipment

Get expert help to find the right pump

The right pump ensures stable, efficient, and reliable production. At Hans Buch, we know Alfa Laval’s wide range of pumps and can help you find the optimal solution.

Whether you need a gentle solution for sensitive products, a robust pump for demanding applications, or a flexible model that handles both product flow and CIP, we can guide you to the optimal solution.

Contact us for advice, so you get a pump that matches your specific needs.