Valves | Double seat valves

Alfa Laval’s double seat valves are developed for processes where reliable separation of incompatible liquids is crucial. The valves have an advanced design with two seats and a drainable leakage zone that effectively prevents cross-contamination – even with pressure variations and during CIP/SIP.

With high operational reliability, flexible construction, and easy maintenance, these valves are ideal for the food, beverage, dairy, personal care, and pharmaceutical industries.

At Hans Buch, we offer the entire range of Alfa Laval’s double seat valves – with advice, configuration, and technical support, so you get the solution that fits precisely to your plant.

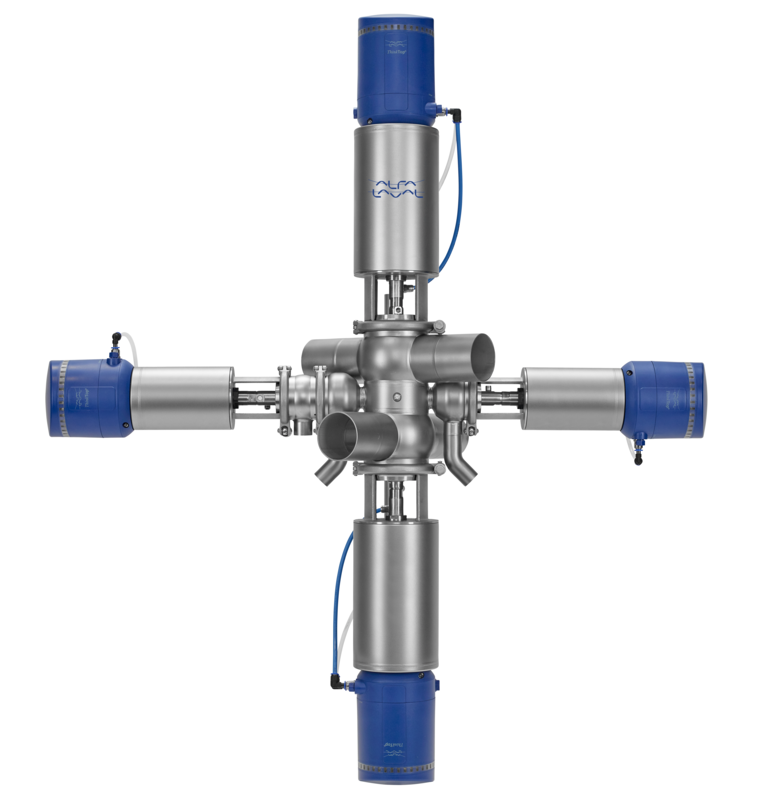

Alfa Laval Aseptic Mixproof

Alfa Laval Aseptic Mixproof is an advanced double seat valve designed for aseptic and sterile applications where product safety and hygiene are paramount. The valve safely separates incompatible liquids via two independent seats and an atmospheric leakage zone, preventing cross-contamination even under pressure.

With steam barriers and full CIP/SIP compatibility, it is ideal for the dairy, food, beverage, biotech, and pharmaceutical industries. It supports validation and documentation in regulated environments, ensuring high uptime and easy maintenance.

Alfa Laval Unique Mixproof

Alfa Laval Unique Mixproof is an advanced double seat valve that enables the safe handling of two different liquids through the same valve – without the risk of cross-contamination. The valve has two independent seats with an atmospheric leakage zone in between, which effectively protects the product and process.

It is ideal for automated process lines in the food, dairy, beverage, and personal care industries, where high hygiene, flexibility, and operational reliability are crucial. The valve supports full CIP and SIP, and its modular design makes maintenance simple and quick.

Alfa Laval Unique Mixproof 3-Body

Unique Mixproof 3-Body is an advanced double seat valve designed for the simultaneous handling of multiple liquid streams, e.g., product and CIP, without the risk of cross-contamination. The flexible 3-part construction makes it ideal for complex and automated process lines in the food, dairy, and beverage industries.

The valve ensures high hygiene, is fully CIP/SIP compatible, and easy to maintain – a reliable solution for efficient flow management.

Alfa Laval Unique Mixproof CIP

Unique Mixproof CIP is a compact double seat valve specifically designed to separate CIP liquids from product streams in hygienic process plants. The valve ensures complete liquid separation, minimizes the risk of cross-contamination, and is ideal for the food, dairy, and beverage industries.

With its simple construction and efficient function, it is an obvious choice for automatic cleaning, where space and operational reliability are in focus.