Pumps for food and pharmaceuticals

Unmatched pumps targeting strict quality standards

At Hans Buch, you will find pumps from Alfa Laval, which is one of the market’s leading manufacturers with design and development aimed at handling the production of food, beverages, and pharmaceutical products. The range offers robust design, easy maintenance, and features that have the perfect balance between gentle and efficient liquid transfer.

Specialized pump range for strict quality requirements

At Hans Buch, you will find a pump range that is specifically designed and developed to handle liquid processes and filling in industries subject to strict quality requirements in terms of hygiene and consistency.

This is characteristic of industries within the production of food, beverages, and pharmaceutical products, where the slightest impact can change the properties of the final product if not handled correctly with the right components and products. This calls for specialized technical solutions of pumps, which Hans Buch provides technical advice and deliveries of in collaboration with Alfa Laval.

Superior pump solutions in collaboration between Hans Buch and Alfa Laval

The collaboration between Hans Buch and Alfa Laval is a technological match that blends decades of experience with technical advice from Hans Buch’s specialists and Alfa Laval’s unique pump solutions. The collaboration provides you with the very best conditions for a specialized solution that meets unique adaptations to your processes in accordance with the industry’s requirements for strict quality standards.

With pumps from Alfa Laval’s range and Hans Buch’s holistic approach to your business and applications, you get a wide selection of pumps that contribute to your processes, taking care of the legislation and internationally recognized certifications that your company commits to comply with.

A range in perfect balance between efficiency and gentleness

At Hans Buch, we offer a specialized range of pumps from Alfa Laval, targeted at industries within the production of food, beverages, and pharmaceutical products.

These industries are characterized by being subject to strict standards to maintain consistent and high quality and hygiene. This calls for specialized solutions that effectively and gently handle liquid transfer, without affecting the properties of the liquids during the process both internally in the applications and externally from contamination.

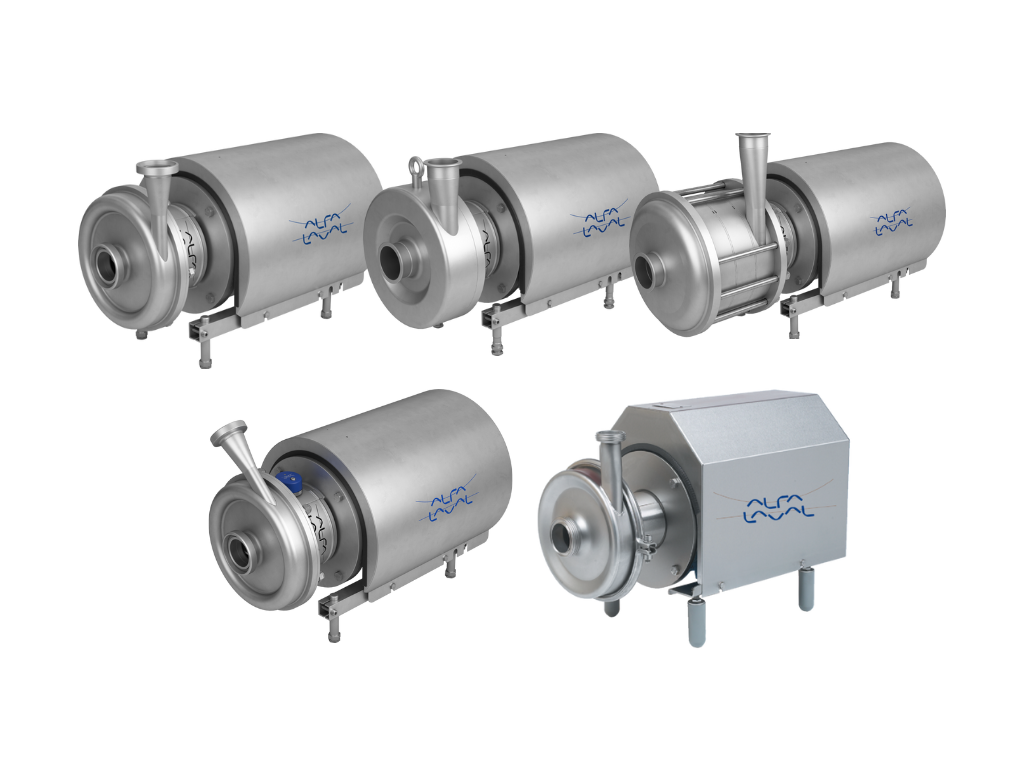

Centrifugal Pumps

Centrifugal Pumps from Alfa Laval.

The centrifugal pumps in Alfa Laval’s LKH UltraPure series are known for being cost-effective and suitable for pharmaceutical production, which is subject to strict requirements. When you choose these pumps, you get full transparency for all processes regarding procurement, production, and supply chains, as well as full traceability.

The range also covers the MR series, which is specifically designed to pump liquids containing air or gases. The MR pumps are self-priming and suitable for CIP return applications. Additionally, there is the SolidC series, which is designed for general industrial use and is suitable for systems with high hygienic requirements in the production of dairy products, food, and beverages.

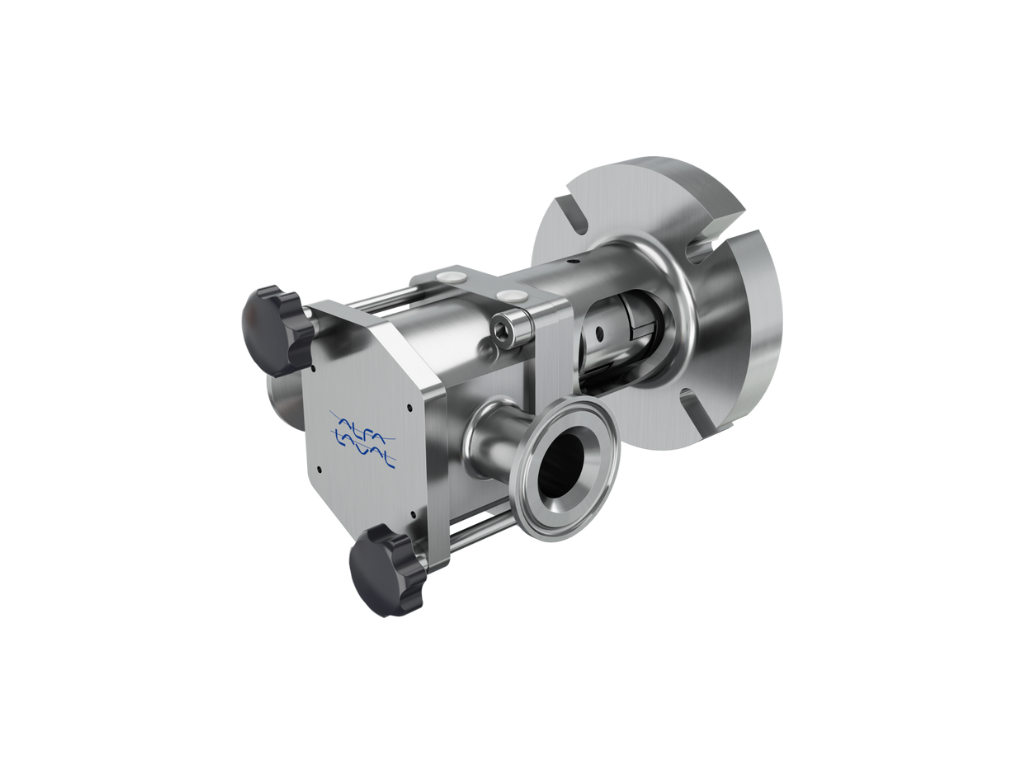

Lobe Rotor Pumps

Circumferential Piston Pumps from Alfa Laval.

Alfa Laval’s Lobe Rotor Pumps are found in the DuraCirc® series, which offers high durability, operational reliability, efficiency with unmatched hygienic properties, and performance with high volumetric efficiency. DuraCirc® is specifically designed for processes where products with very low viscosity and higher discharge pressure are transported. This includes, for example, food, dairy products, and beverages, as well as other hygienic applications.

With DuraCirc®, you achieve high flexibility and reduced costs thanks to a wide range of models and functional options within flow rates and pressures. This allows for a solution that fits precisely to the task you need to solve. The DuraCirc® Aseptic variant is, as the name suggests, the right choice for aseptic environments, where it is crucial for quality assurance that the production of, for example, food and pharmaceutical products is sterile and thus free from microorganisms that can cause contamination.

The range of lobe rotor pumps is designed to handle media with low, medium, and high viscosity. The series of lobe rotor pumps consists of SX, SRU, and OptiLobe, and regardless of your specific need, the range meets the requirements for high standards.

Common features are good operational economy and flexibility, and the lobe rotor pumps provide gentle pumping action and reliable performance. The SX series is well-suited for general purposes with easy service, while the SRU series is suitable for gentle liquid processes within dairy, food, and beverages. The SX series is targeted at pharmaceutical applications for hygienic and ultra-clean environments.

Twin Screw Pumps

Twin Screw Pumps from Alfa Laval.

Achieve high process flexibility with Alfa Laval’s twin screw pumps, which are built robustly and designed to meet strict hygiene requirements demanded in applications for dairy, food, and beverages, where gentle processes are also a necessity to ensure the quality of consumer products.

With these pumps, simple maintenance is achieved. The pumps handle both product transfer and CIP (cleaning-in-place), and the low pulsating properties reduce the risk of product damage and ensure increased operational stability.

Gear Pumps

Gear Pumps from Alfa Laval.

Gear pumps from Alfa Laval provide improved process flexibility and operational reliability for filling processes with efficient transfer of liquids in low volume. The pumps allow for precision adjustments, easy cleaning, and simple maintenance thanks to the interchangeable parts, including mechanical seals, cover plates, back plates, and o-rings. Disassembly is therefore an easy task on-site when maintenance is required.

With easy adjustments, the series of gear pumps is an obvious choice for the OEM developer of filling machines for both hygienic and general industrial applications. Therefore, it is a popular and widespread solution for a wide range of industries producing food, chemicals, personal care, and much more.

The M series of gear pumps from Alfa Laval is available in three variants that can be adapted to your specific process requirements. Choose different pump head sizes, flow rates up to 1500 liters per hour, differential pressures up to 7 bar, and temperatures up to 60 degrees. With a bracket, the pump can be freestanding, allowing for flexible and modular construction of your application.